Safety Stock Optimization: Advanced

Safety Stock Optimization Solution Method

You can select the solution method that Safety Stock Optimization will use to solve the MEIO (multi-echelon inventory optimization), depending on the complexity of your model. In most cases, Coupa recommends that you use the "Automatic" setting, enabling the solver to select the appropriate method. The available solution methods are:

Automatic – The solver automatically selects the method to solve the problem based on the problem size and structure. "Automatic" is typically used for most models.

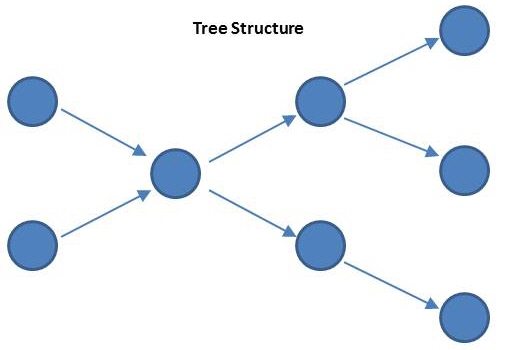

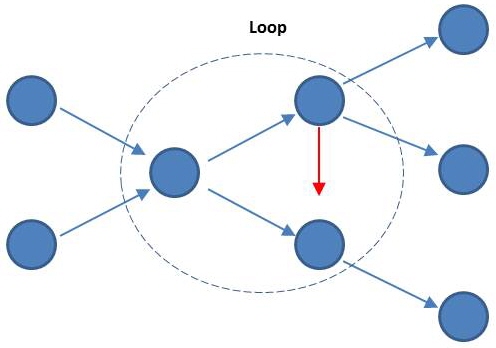

Dynamic Programming – Dynamic Programming (DP) solves fast and solves to optimality for small models and tree structure networks. It breaks down the problem into multiple sub-problems that are solved in stages. DP also uses heuristics for networks containing loops.

Linear Programming – Linear Programming (LP) handles large network with loops and solves to a gap percentage depending on the maximum solve time. .

For additional information, refer to Linear programming and mixed integer linear programming.

Piecewise Node

Select a value of 3 through 9 to define the piecewise node. This setting applies to linear programming (LP) only.

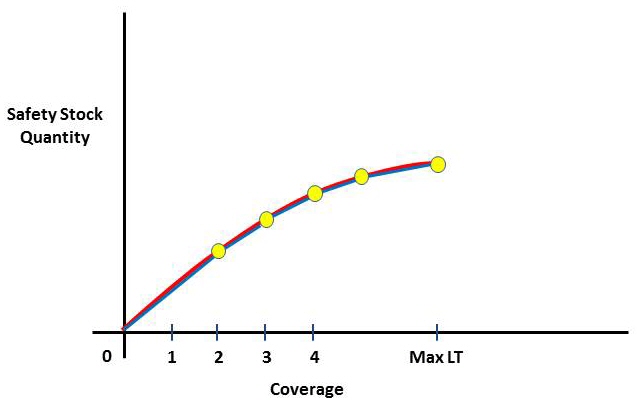

The safety stock curve is an input to the linear programming optimization. The piecewise approximation is used to capture characteristics of the safety stock curve. The number of nodes defines the limits to which potential solutions are excluded from analysis. Increasing the number of piecewise nodes applied to the safety stock optimization increases the approximation precision, which can provide a more accurate safety stock optimization solution. This increased accuracy typically results in an increased solve time.

To set this value in a scenario, select “Inventory Optimization Options” as the table, “Piecewise Node” as the field and enter a number between 3 and 9 as the value.

Default: 5

Inventory Policy Override

Use this setting to override the current inventory policy with one of the following:

- None – When this value is selected, the inventory policy is not overridden.

- R,Q Policy

- s,S Policy

- T,S Policy

- BaseStock Policy

For details about each of the policies, refer to Supported inventory policies.

To set this value in a scenario, select “Inventory Optimization Options” as the table, “Inventory Policy Override” as the field and select one of "None", "R,Q Policy", "s,S Policy", "T,S Policy" or "BaseStock Policy".

Post Process Random Lead Time

In Safety Stock Optimization, the lead time variability (including production time, transport time and sourcing lead time) is assumed to be evenly distributed across the network. If you select the Post Process Random Lead Time option, after the optimization on safety stock placement is done, the safety stock is recalculated based on the coverage and the lead time variability associated with that site. The default value for this option is selected.

To turn this option off in a scenario, select “Inventory Optimization Options” as the table, “Post Process Random Lead Time” as the field and select "No" as the value.

Single Solution Multi-Period

In a multi-period model, each period is assumed to be independent. However, that would produce different safety stock placement decisions for each period. Many modelers find it hard to implement the safety stock placement period by period. If you select Single Solution Multi-Period, all periods are considered simultaneously to determine one safety stock placement strategy. Note that for this feature to work, the network structure cannot change from period to period.

To set this value in a scenario, select “Inventory Optimization Options” as the table, “Single Solution Multi-Period” as the field and select "Yes" as the value.

Calculate Upstream Service Failure

You can define lower service levels for upstream sites (such as manufacturing plants) in comparison to downstream sites (such as distribution centers). When this option is selected, Safety Stock Optimization calculates the amount of additional safety stock downstream needed due to a lower upstream service defined.

To set this value in a scenario, select “Inventory Optimization Options” as the table, “Calculate Upstream Service Failure” as the field and select "Yes" as the value.

Lead Time Bucket Precision (Days)

This value is the interval of time used to construct the safety stock curve. The default value is "Auto", but you can enter a precision in units of DAY. The Lead Time Bucket Precision should be an integer of the demand Aggregation Level (Demand Analysis tab) to prevent a loss of precision. When setting this value in a scenario, select the “Lead Time Bucket Precision (Days)” Inventory Optimization Options field and enter "Auto" or enter the number of days.

Last modified: Friday May 12, 2023