Type 3 (Ready Rate)

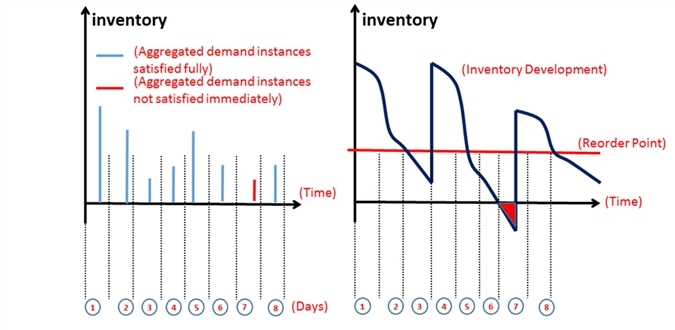

Type 3 is the fraction of time where the period demand is fully satisfied immediately. In Safety Stock Optimization, period demand refers to the total demand aggregated within the desired aggregation level (i.e. day, week or month). Notice that any aggregated demand instance not fully satisfied immediately creates a stock out in the system. This can be explained by the following figures. Note that Type 3 is similar to Type 2 in the sense that they both calculate the expected shortage during a cycle. Type 2 calculates the shortage in quantity, while Type 3 calculates the shortage in time. Moreover, Type 3 also considers the backorder created by a small batch size. For Type 2 or Type 3, all stocking sites in the network must have either Replenishment Frequency (RF) or Minimum Order Quantity (MOQ) populated. If any sites do not have at least one of these values defined, the Service Definition is switched to Type1.

Coupa recommends that you set the Replenishment Frequency (RF) when using Type 2 (Quantity Fill Rate), since it is more accurate in representing the statistics than MOQ.

On day 7, the demand instance is not immediately satisfied by the inventory system. This can be observed in the second figure where the net inventory falls below zero (i.e. shortage).

In this respect, Type3 also refers to the probability of no stockout in any given aggregation level; that is the fraction of time with positive stock on-hand. It is both event-oriented and based on the duration of the event: Was there a stockout in the aggregation level and what was the duration of the stockout?

The ready rate (RR) is determined as:

RR = 1 - (Nb/Np)

where

Nb is the number of aggregation levels with stockouts

Np is the number of total aggregation levels in the horizon.

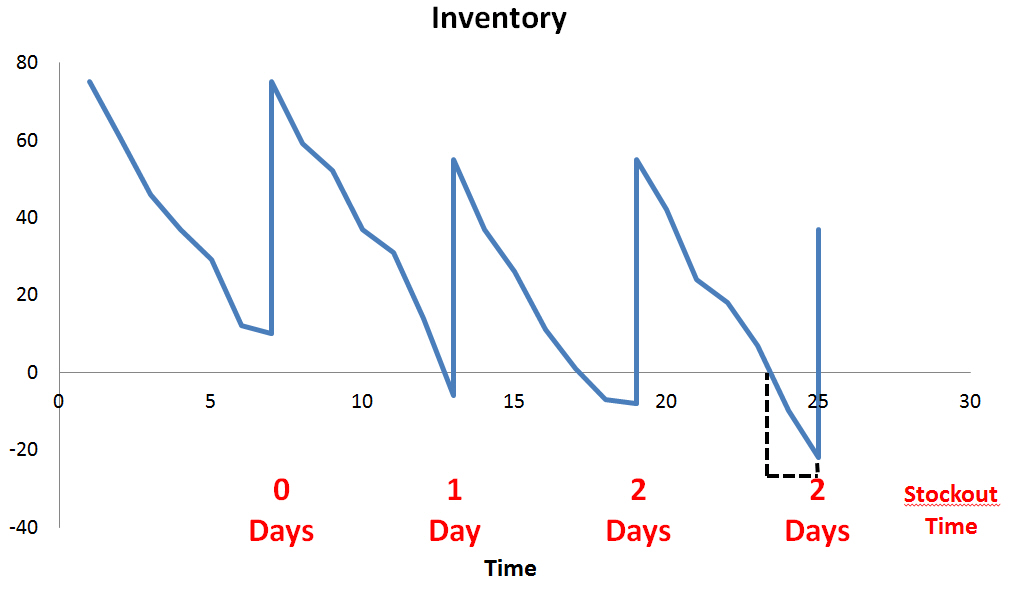

In the example below, daily aggregation is used and there are 25 days total. Stockouts occur for 5 of those days:

(0 + 1 + 2 + 2) = 5 days

The Type 3 Service level is:

(25 - 5) / 25 = 80%

Last modified: Wednesday May 15, 2024