Technology Constraints options

Model Constraints

Enforce By Period options:

- Site Single Sourcing: When this option is not selected, the site single sourcing is locked at the horizon level. When this option is selected, it forces each site to source product from only one location during each period in the model. To select this option in a scenario, select Network Optimization Options as the table and “Site Single Sourcing” as the field and select "Yes" as the value (the default for this option is off).

- Product Single Source: When this option is not selected, the site-product single sourcing is locked at the horizon level. When this option is selected, it forces each site to source each product from only one location during each period in the model. To select this option in a scenario, select Network Optimization Options as the table and “Product Single Sourcing” as the field and select "Yes" as the value (the default for this option is off).

- Single BOM Sourcing: When this option is not selected, the site-product single sourcing is locked at the horizon level where the Assignment Policy is “Single BOM” in the Bill Of Material Assignments table. When this option is selected, it forces each site to source each product from only one location during each period in the model. To select this option in a scenario, select Network Optimization Options as the table and “Single BOM Sourcing” as the field and select "Yes" as the value (the default for this option is off).

- Single Process Sourcing: When this option is not selected, the site-product single sourcing is locked at the horizon level where the Assignment Policy is “Single Process” in the Production Process Assignments table. When this option is selected, it forces each site to source each product from only one location during each period in the model. To select this option in a scenario, select Network Optimization Options as the table and “Single Process Sourcing” as the field and select "Yes" as the value (the default for this option is off).

- Single Routing Rule: When this option is not selected, the Routing Policy is locked at the horizon level where the Processes Routing Policy is “Single Route”. When this option is selected, it forces the single route during each period in the model. To select this option in a scenario, select Network Optimization Options as the table and “Single Routing Rule” as the field and select "Yes" as the value (the default for this option is off).

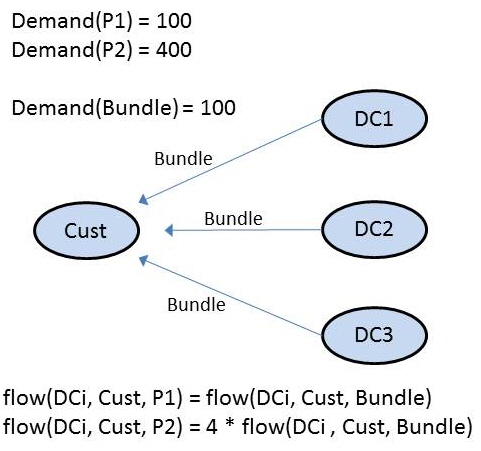

Bundle Demand: When this option is selected, Network Optimization combines all customer demands into one single constraint. Ratios are established between demands of various products. Within the optimization, the individual product flows are replaced by a single bundle flow.

The intent of this feature is to simplify the model by aggregating all the demand for each customer. For each source-customer combination, Network Optimization creates a single lane that bundles all products, rather than lanes for each product. Bundle Demand assumes that the products flowing to the customer will be proportionally sourced from all connected locations. Assume Customer Order records such as:

| Customer | Product | Quantity |

| CZ | Prod_1 | 9 |

| CZ | Prod_2 | 1 |

Flow capacity per lane from DCs to customer:

| Source | Destination | Quantity |

| DC1 | CZ | 5 |

| DC2 | CZ | 5 |

Flow to customer per lane:

| Product | Flow |

| Prod_1 | 4 |

| Prod_2 | 1 |

Demand bundling is feasible only if at least one of the sources connected to a customer is able to supply/produce all the products demanded by a customer. For example, assume your model has two products, each of which can be produced and supplied by two DCs. The Production Policies are:

| Site Name | Product Name | Production Policy |

| DC1 | Prod_1 | Make |

| DC1 | Prod_2 | Make |

| DC2 | Prod_1 | Make |

| DC2 | Prod_2 | Make |

And the Customer Sourcing Policies are:

| Source Name | Customer Name | Product Name | Sourcing Policy |

| DC1 | CZ | Prod_1 | Multiple Sources(Most Inventory) |

| DC1 | CZ | Prod_2 | Multiple Sources(Most Inventory) |

| DC2 | CZ | Prod_1 | Multiple Sources(Most Inventory) |

| DC2 | CZ | Prod_2 | Multiple Sources(Most Inventory) |

In this case, both products will be produced and supplied to the customer by one of the DCs, such as:

| Source Name | Customer Name | Product Name |

| DC1 | CZ | Prod_1 |

| DC1 | CZ | Prod_2 |

The selection of the DC will depend on any costs and constraints associated with the sites.

Assume that you now exclude Production Policies (for example, in a scenario definition) such that each DC produces only one of the products:

| Site Name | Product Name | Production Policy |

| DC1 | Prod_1 | Make |

| DC2 | Prod_2 | Make |

In this case, demand bundling cannot be accomplished and the scenario is infeasible.

To select this option in a scenario, select Network Optimization Options as the table and “Bundle Demand” as the field and select "Yes" as the value (the default for this option is off ).

Notes regarding bundle demand usage:

- The Bundle Demand option should not be used in combination with other demand constraints. These constraints are the Classify Demand by Due Date constraint and the constraints that result when you define Mode on the Customer Orders table (in which case the demand must be served by that Mode).

- Bundle Demand is a legacy feature. It may not be applicable with newer parameters or constraints.

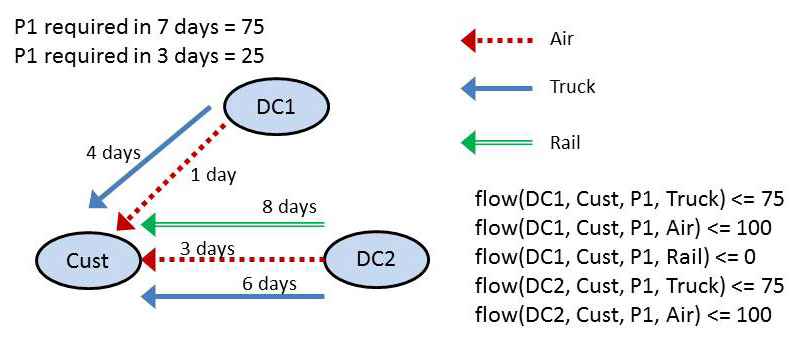

Classify Demand By Due Date: When this option is selected, Network Optimization aggregates demand by Due Date in Customer Orders as opposed to Order Date. The demand with due date constraints will not be able to use any mode or lane that is longer than the Service Level, effectively adding bounds to the flow variables. The Due Date or Service Level is used along with the Order Time or Order Time Formula to determine the lead time required. If both Due Date and Service Level are populated, the Service Level takes precedence.

To select this option in a scenario, select “Classify Demand by Due Date” as the field and select "Yes" as the value (the default for this option is off).

Use Only Customer Flows For DOS: If you select this option, Days of Supply calculations will be performed only for Customer Flows, not for InterSite Flows. If you have inventory constraints that restrict DOS, then only those flows will be included in the constraint and it does not apply to non-customer destinations. To select this option in a scenario, select “Use Only Customer Flows For DOS” as the field and select "Yes" as the value (the default for this option is off).

End To End Service Constraints

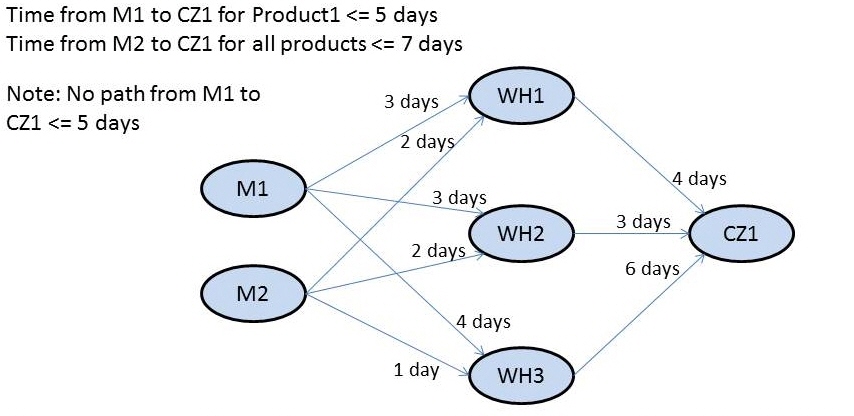

Ignore Infeasible Constraints: If you select this option, end to end service constraints that result in no valid paths from the "Make" site to the customer will be ignored. If this option is not selected and there are no valid paths, either too far in distance or too long in lead time, the model will return an infeasibility.

End to end service constraints are not guaranteed to work properly if you select one or both of these options:

- Allow flows to extend across periods

- Allow productions to extend across periods

For example, assume both M1 and M2 have paths that satisfy the end to end service constraint (in terms of lead time and/or distance). M2 has a capacity constraint on it so it cannot serve all of the CZ1 demand. The model will not return infeasible (unless there are no other manufacturers that can satisfy the CZ1 demand). In this case, due to the capacity constraint, M2 is not used as a source at all, and another manufacturer is used to serve the demand. To set this value in a scenario, select Network Optimization Options as the table and “Ignore Infeasible Constraints” as the field and select "Yes" as the value.

Multiple Make Paths: If you select this option, flows are allowed to be split over feasible paths from more than one make site to the customers. To set this value in a scenario, select Network Optimization Options as the table and “Multiple Make Paths” as the field and select "Yes" as the value.

Custom Constraints

Custom constraints provide a mechanism to complement the optimization code. It enables you to model behavior that the solver is capable of doing, but the user interface does not support.

You can use special custom dll files to define the custom constraint. If the customization needs additional data, the data can be specified in an accompanying data definition. The data definition can contain the actual data or can specify the schema for user defined input tables that you populate with the data. For advanced use only.

You can also create new custom constraints and import existing constraint files.

- Network Optimization — This option enables you to select an existing custom constraint for use in Network Optimization. To set this value in a scenario, select “Network Optimization Constraint File” as the field and enter the name of the custom constraint.

- Greenfield Analysis — This option enables you to select an existing custom constraint for use in Greenfield Analysis. To set this value in a scenario, select “Greenfield Analysis Constraint File” as the field and enter the name of the custom constraint.

Last modified: Wednesday May 15, 2024