Standard optimization

For this problem, Transportation Optimization creates transportation routes using optional time windows for shipment pickup and delivery. Each shipment can have a unique pickup and delivery window if required. Standard optimization models include:

- Inbound shipment consolidation such as consolidation of goods from multiple suppliers. An example is a company that assembles products that contain components from many suppliers. Transportation Optimization can be used to optimize consolidation of vendor shipments into multi-stop routes which pick up at several vendors before delivering to the assembly location.

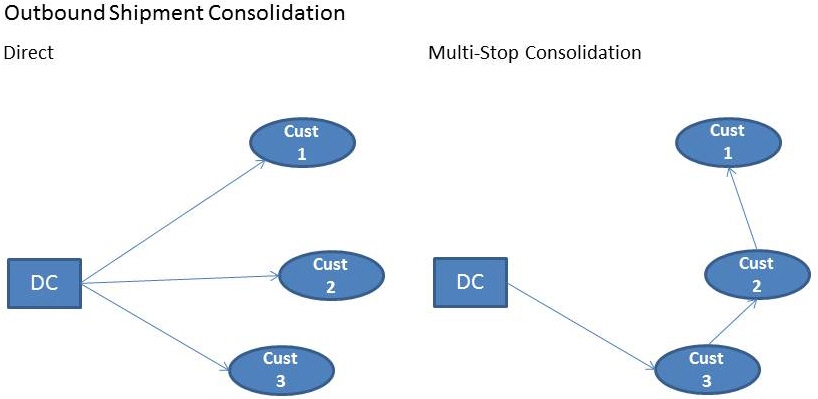

- Outbound shipment consolidation of deliveries. An example is a retailer delivering products from a distribution center to a number of retail stores in the same trip. In this case, the delivery routes are optimized to minimize the cost. Maximum route time and distance can be considered, as well as constraints including those on delivery windows.

In both cases, the objective of Transportation Optimization is to minimize the cost of the routes while limiting the number of routes required. It does this by considering all the costs in the model (such as travel, loading/unloading time, wait and break time, asset fixed cost).

Transportation Optimization evaluates the metrics of the shipments, any pickup and delivery time windows that you have specified, and the characteristics of vehicles (speed, capacity, number available).

The solution is a set of routes, stops, and shipment and vehicle assignments. Stops have details including delivery dates and times.

Standard optimization and direct shipping cost

If you populate the Direct Shipping Cost for Shipments, and the direct shipping cost turns out to be lower than the routed cost, those shipments are unrouted with a reason of “Direct Shipping Cost is cheaper”. Therefore, you will not see routes where the Selected Mode is "Direct Ship".

Standard optimization high level algorithm summary

The following provides a high level review of the standard optimization algorithm:

First, an initial solution construction phase is run to generate an initial solution for each asset type defined. Routes are created and filled with shipments, always inserting the next cheapest shipment first.

Once these initial solutions have been constructed, the algorithm then proceeds into a route generation phase where a very large number of promising new routes are constructed and stored in memory.

Next, an optimization model is solved to pick a set of routes that results in the best possible solution out of the large pool of routes that have been created.

The last step is an improvement phase that attempts to reduce the cost of the current solution. Several swap and interchange improvement heuristics are done to increase the solution quality. Additionally, the algorithm identifies some key performance indices (KPIs) and attempts to improve these metrics. An example of such a KPI is asset utilization. As the improvements decrease or stop, the algorithm does some post processing and present the final solution.

Last modified: Wednesday May 15, 2024