Sourcing Process Steps

Internal Table Name: SourcingProcessSteps

Use the Sourcing Process Steps table to define work centers, times and cost associated with a process step. In addition, you use this table to define how multiple process steps within a process are sequenced.

Simulation: Available only in Classic Simulation.

Period

Technology: NO

Table: SourcingProcessSteps

Internal Name: PeriodName

Type: Short Text (50)

Select the period(s) to which the Sourcing Process Step applies. This can be one of:

- a specific Period Name,

- a Period group name,

- (ALL_Periods) to apply to each period in the model horizon.

Process

Technology: NO S

Table: SourcingProcessSteps

Internal Name: ProcessName

Type: Short Text (100)

Enter the name of the Process to which the Process Step belongs.

Process Step

Technology: NO S

Table: SourcingProcessSteps

Internal Name: ProcessStepName

Type: Short Text (50)

Enter a descriptive name for this particular step of the process that you are specifying.

Next Process Step

Technology: NO S

Table: SourcingProcessSteps

Internal Name: NextProcessStepName

Type: Short Text (100)

Choose the next step of the process. When the process is complete, select (None).

Tip: Define all Process Step values first, then refresh the table. You can then use the drop down to select the Next Process Step value.

Work Center

Technology: NO S

Table: SourcingProcessSteps

Internal Name: WorkCenterName

Type: Short Text (100)

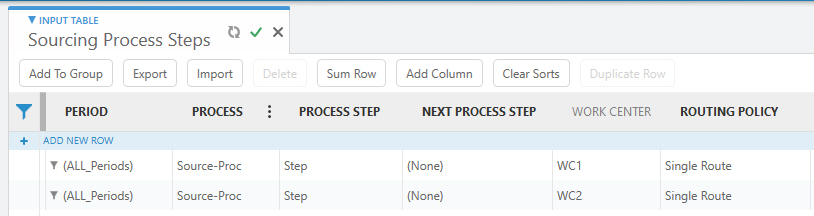

Choose the work center used for this step in the process. When assigning work centers to Sourcing Process Steps, be sure that the record has a unique combination of Period-Process-Process Step-Next Process Step. For example, consider the following records:

In this case, the two records are considered duplicates, even though they have different Work Center values. Only one of them will be included when the model is solved. This can cause the model to be infeasible.

When assigning work centers to sites for process modeling, the correct assignment of a Site value in the Work Centers table depends on the Sourcing Process Type as listed below:

-

Create Order - The work center should be assigned to the destination site.

-

Send Order - The work center should be assigned to the destination site.

-

Receive Order - The work center should be assigned to the source site.

If you assign a work center, and that work center is not at the site the process type is mapped to, process steps using this work center are not excluded. The process is still available, but it is now invalid, since the required work center is not available. This condition is related to work center maximum throughput constraints. It can result in a feasible model that should actually be infeasible.

If you delete a work center, you are prompted if you want to delete rows from dependent tables (in this case, the Sourcing Process Steps table).

Routing Policy

Technology: NO S

Table: SourcingProcessSteps

Internal Name: RoutingRule

Type: Short Text (50)

One of Single Route, Multiple Routes (First Available), Multiple Routes (Most Capacity), Multiple Routes (Probability).

Specify if there is one possible route (Single Route option) for this process or if there are more routes possible.

Simulation: Options include Single Route, Multiple Routes (First Available), Multiple Routes (Most Capacity) and Multiple Routes (Probability).

Optimization: Options include Single Route and Multiple Routes (Probability).

| Routing Policy | Description |

|---|---|

| Single Route | Use this Routing Policy if there is only one possible route for the process to use. |

| Multiple Routes (First Available) | Simulation: When you use this rule, Simulation selects the work center with the lowest step number. If this work center is busy, it moves on to the next step. If the next step is busy, it moves on to the next and so on until it reaches the last step. If all of the steps/work centers are occupied, then the step with the lowest step number would be picked regardless of its queue length. |

| Multiple Routes (Most Capacity) | Simulation: When you use this rule, Simulation selects the work center with the most available capacity. |

| Multiple Routes (Probability) | Use this rule if you want to set a probability for each of the routes that can be used by the process. Specify the probability value in the Routing Route Parameter field. |

Default: Single Route

Using Multiple Routes

When using Multiple Routes (First Available) for a large number of orders within a short time frame, you may see idle work centers. This can occur if orders are initially assigned to one or more work centers. Once those work centers are busy with orders, additional orders will be queued up at the first work center (WC1). Even if another work center (WC2) finishes, orders are not sent to WC2 because they have already been queued up at WC1. If another demand is scheduled after WC2 is finished producing, WC2 will then be selected.

Work center steps process orders sequentially and the order is not released until it is complete. Each order queued up for a step must wait until the previous order is complete or select an alternate route if available.

Policy Parameter

Technology: NO S

Table: SourcingProcessSteps

Internal Name: RoutingRuleParameter

Type: Number (Long Integer)

This is only applicable if the Routing Rule is set to Multiple Routes (Probability). Enter the percentage of probability that this process will use the specified Next Process Step (can also be (None)). If the chance is 25% that the specified Next Process Step will be used, enter "25".

If the Policy Parameters add up to more than 100, the smallest percentage is adjusted down to equal 100. For example, if two Processes records have Policy Parameter values of 70 and 50, the value of 70 will be used, then the 50 will be adjusted to 30.

If the Policy Parameters add up to less than 100, these values are adjusted based on their percentage of the total. For example, if two Processes records have Policy Parameter values of 60 and 15, the total is 75. The value of 60 is 80% of the total, while 15 is 20%, so the values will be adjusted to their percentage of the total.

Default: 1

Unit Process Cost

Technology: NO S

Table: SourcingProcessSteps

Internal Name: UnitCost

Type: Short Text (50)

Enter the cost for each unit for this process step. This applies to the Quantity unit of measure in Model Settings. Each step in a process can have a different cost. For example, as an order lot goes through each routing step, costs accumulate until the order is complete. The total cost of the order is then added to the site production cost statistics.

The Unit Process Cost is reflected in the Total Sourcing Cost in the Network Summary output tables. In Simulation, the specific Unit Process Cost by process step is reflected in the Variable Process Cost in the Process Transactions output table.

Default: 0

Fixed Lot Setup Cost

Technology: NO S

Table: SourcingProcessSteps

Internal Name: SetupCost

Type: Short Text (50)

Specify the initial costs for implementing the process step. Fixed Lot Setup Costs are applied for each batch, i.e. the Fixed Lot Setup Costs are calculated based upon the Order Lot Size and the number of units processed. For example, if the order is for 500 and the Order Lot Size is 100, then 5 lots will be produced.

The Fixed Lot Setup Cost is reflected in the Total Sourcing Cost in the Network Summary output tables. In Simulation, the specific Fixed Lot Setup Cost for each process step and lot is reflected in Setup Cost in the Process Transactions output table.

Default: 0

Unit Process Time

Technology: NO S

Table: SourcingProcessSteps

Internal Name: UnitTime

Type: Short Text (50)

Enter the process time required for each unit. This applies to the Quantity unit of measure in Model Settings. This time unit can accept both probability distributions and straight time units (SEC, MIN, HR, DAY, WK). If the process specifies production for example, the Unit Process Time is multiplied by the quantity of ordered product, to arrive at a total production time for this step.

Example: The Unit Process Time at the Lemonade Squeezing step is 6 SEC. The total production time per unit for 1000 lemons is 6000 seconds or 100 minutes.

Default: 0

Fixed Order Process Time

Technology: S

Table: SourcingProcessSteps

Internal Name: OrderTime

Type: Short Text (50)

Enter the fixed amount of time required for each order that goes through this step, regardless of the production quantity. Enter a value, then optionally select a time unit of measure. If you do not select a unit of measure, the default Time Unit Of Measure from Model Settings is used. The Fixed Order Process Time includes time for such tasks as setup and changeover times. It is not exclusive of the Unit Process Time; you can have both a Fixed Order Process Time and a Unit Process Time.

The Fixed Order Process Time field acts as a setup time for individual orders. For example, assume that you have a Order Lot Size of 2, Quantity of 5 and a Fixed Order Process Time value of 1 HR. You will have 3 orders - 2 orders for 2 units and 1 order for 1 unit. Each of these three orders incurs the 1 HR of Fixed Order Process Time added to the total sourcing cost.

Keep in mind that the number of orders calculated is based on each demand order specified. If you have 5 units of demand on March 14, this would be 3 orders and 7 units on March 21 would be 4 orders based on the example Order Lot Size. The demand is not summed up over the horizon to calculate the number of orders.

The total sourcing cost is:

(Unit Process Cost * Units) + (Fixed Lot Setup Cost * # of orders)

Default: 0

Move Time

Technology: S

Table: SourcingProcessSteps

Internal Name: MoveTime

Type: Short Text (50)

Enter the amount of time it takes to move the product from this process step to the next in case a next process step is specified in the Next Process Step field.

Average Changeover Time

Technology: NO

Table: SourcingProcessSteps

Internal Name: AvgChangeoverTime

Type: Short Text (50)

Enter the average fixed amount of time required for each order that goes through this step. The Average Changeover Time includes time for such tasks as setup and changeover times. It is not exclusive of the Unit Process Time; you can have both a fixed Average Changeover Time and a Unit Process Time.

The Average Changeover Time field acts as a setup time for individual orders. For example, assume that you have a Order Lot Size of 10, Quantity of 60 and Average Changeover Time value of 2 HR. Optimization determines the number of orders as 6 (that is, the total production amount / the Order Lot Size, or 60 / 10). It would therefore incur a total changeover time of 12 HR. Also, assume a Unit Process Cost of 5 and Fixed Lot Setup Cost of 25.

For Network Optimization, the total sourcing cost is as defined below:

If Average Changeover Time is greater than 0:

Total Sourcing Cost = (Unit Process Cost * Units) + (Fixed Lot Setup Cost * # of orders)

Using the example above, this is (5 * 60) + (25 * 6) = 300 + 150 = 450

If Average Changeover Time is not defined or equals 0:

Total Sourcing Cost = (Unit Process Cost * Units)

Average Changeover Time is not used in Simulation. For Simulation, the Fixed Lot Setup Cost is incurred for each lot, regardless of the value of Average Changeover Time.

Default: 0

Resource

Technology: NO S

Table: SourcingProcessSteps

Internal Name: WorkResourceName

Type: Short Text (100)

Choose the work resource that will be assigned to this process step.

Resource Time (Hours)

Technology: NO

Table: SourcingProcessSteps

Internal Name: WorkResourceUsageInHours

Type: Short Text (50)

In Optimization, specify the number of hours the resource is used for this process step. This column is not used in Simulation as the time a resource is used is determined by:

(Lot Size * Unit Process Time) + Fixed Order Process Time

Order Lot Size

Technology: NO S

Table: SourcingProcessSteps

Internal Name: LotSize

Type: Short Text (50)

Enter the Order Lot Size for this process step. The Order Lot Size is used to break up a production quantity into smaller amounts. For example, if a production quantity of 1000 starts a process step with an Order Lot Size of 100, the production item will cause 10 items of 100 each to be produced.

To enforce an integer number of production lots:

- The Unit Process Cost or the Fixed Lot Setup Cost (or both) must be populated for the Process Step used, and

- You must select the “Enforce integer number of production lots” optimization option (on the Modeling Options tab).

For example, you would need both these conditions to be met if your Order Lot Size is 100, Quantity is 750, and you expect the production to be 800 (a multiple of 100).

Minimum Order Quantity

Technology: S

Table: SourcingProcessSteps

Internal Name: MinimumLotSize

Type: Number (Float)

Use this field to enforce a minimum batch size in the process. The Minimum Order Quantity enables you to specify the minimum number of units that must be produced at a time. It prevents a process step from producing if this threshold is not met. In contrast, the Order Lot Size field serves as a capacity (breaking quantities into pieces if necessary). For example, if you have an order for 25 units coming to a process that has a minimum Order Lot Size of 50, the process will produce a lot of 50.

Yield

Technology: NO S

Table: SourcingProcessSteps

Internal Name: Yield

Type: Short Text (50)

Enter the loss factor due to this process step. For example, if 10% of the material that was input to a cutting production step (making skewed edges straight) is lost due to the cutting, the yield factor is equal to 0.9: 90% of the material that was inputted is outputted after this production step. In Optimization, demand (from a customer/site or input of the next work center) determines the net production, that is the amount that needs to be output of a certain work center. The input needed at a work center (gross production) is calculated from the demand and the yield value.

Default: 1

Status

Technology: NO S

Table: SourcingProcessSteps

Internal Name: SourcingProcessStepsStatus

Type: Short Text (25)

One of Include, Exclude.

Choose the process step status:

- Include - This process step is to be included in a simulation or optimization run.

- Exclude - This process step is to be excluded from a simulation or optimization run.

Default: Include

Custom 1

Technology: NO S

Table: SourcingProcessSteps

Internal Name: Custom1

Type: Short Text (255)

Optional field to enter descriptive information.

Custom 2

Technology: NO S

Table: SourcingProcessSteps

Internal Name: Custom2

Type: Short Text (255)

Optional field to enter descriptive information.

Last modified: Wednesday May 15, 2024