Site Product Summary

Internal Table Name: SimulationOutputSiteProductDetail

This table shows detailed information at the site-product level, including inventory values. This table contains a unique record for each site, product, scenario, replication and period combination.

Scenario

Table: SimulationOutputSiteProductDetail

Internal Name: Not Applicable (Scenario column not in table)

Displays the name of the scenario which generated the site-product detail data.

Product Name

Table: SimulationOutputSiteProductDetail

Internal Name: ProductName

Displays the name of the product referred to in the report.

Site Name

Table: SimulationOutputSiteProductDetail

Internal Name: SiteName

Displays the name of the site referred to in the report.

Organization Name

Table: SimulationOutputSiteProductDetail

Internal Name: OrganizationName

The Organization to which the site-product details are allocated. When the product is assigned to a Site that belongs to the Organization, the site-product details are attributed to the Organization as required.

Total Demand

Table: SimulationOutputSiteProductDetail

Internal Name: TotalDemand

If the site has demand (as defined in the Site Demand table), this is the total demand for the site in the period.

Total Revenue

Table: SimulationOutputSiteProductDetail

Internal Name: TotalRevenue

If the site has demand (as defined in the Site Demand table), this is the total revenue for the site in the period based on product Price.

Lost Demand

Table: SimulationOutputSiteProductDetail

Internal Name: LostDemand

Displays the number of units demanded by the site that were canceled or lost during the specified period.

Lost Revenue

Table: SimulationOutputSiteProductDetail

Internal Name: LostRevenue

Displays the lost revenue due to canceled or lost units demanded by the site during the specified period.

Initial Inventory Units

Table: SimulationOutputSiteProductDetail

Internal Name: InitialInventoryUnits

Displays the inventory of the product at the site at the beginning of the period.

Average Inventory Units

Table: SimulationOutputSiteProductDetail

Internal Name: AverageInventoryUnits

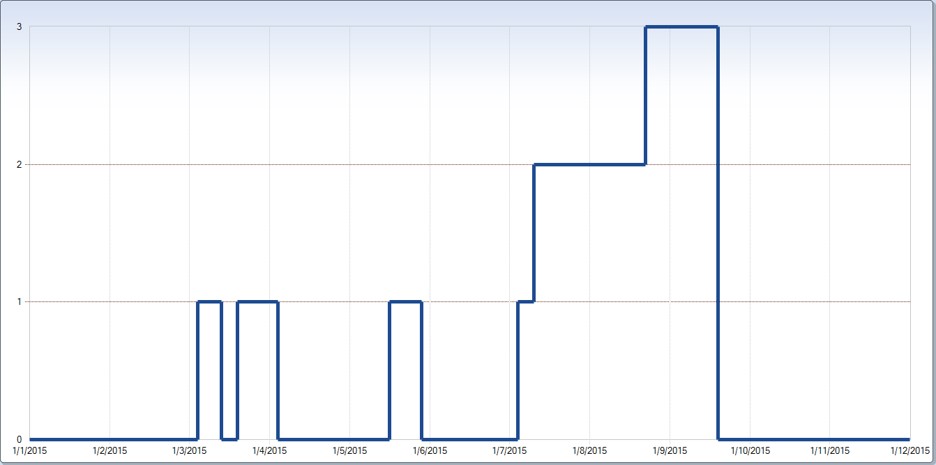

Displays the time-weighted average inventory for this product at this site in the specified period:

where:

U = Inventory Units

T = Time

P = Total time in the period

n = change in U

For example, assume time series inventory levels such as:

The events are:

| Event Time | Site | Product | Time Lapse (Days) |

Inventory Qty per Time |

On Hand Inventory |

|---|---|---|---|---|---|

| 1/1/2015 00:00 | MFG | PRODUCT_A | - | - | |

| 1/3/2015 02:24 | MFG | PRODUCT_A | 2.1 | 0 | 0 |

| 1/3/2015 09:36 | MFG | PRODUCT_A | 0.3 | 0.3 | 1 |

| 1/3/2015 14:24 | MFG | PRODUCT_A | 0.2 | 0 | 0 |

| 1/4/2015 02:24 | MFG | PRODUCT_A | 0.5 | 0.5 | 1 |

| 1/5/2015 12:00 | MFG | PRODUCT_A | 1.4 | 0 | 0 |

| 1/5/2015 21:36 | MFG | PRODUCT_A | 0.4 | 0.4 | 1 |

| 1/7/2015 02:24 | MFG | PRODUCT_A | 1.2 | 0 | 0 |

| 1/7/2015 07:12 | MFG | PRODUCT_A | 0.2 | 0.2 | 1 |

| 1/8/2015 16:48 | MFG | PRODUCT_A | 1.4 | 2.8 | 2 |

| 1/9/2015 14:24 | MFG | PRODUCT_A | 0.9 | 2.7 | 3 |

| 1/11/2015 23:59 | MFG | PRODUCT_A | 2.4 | 0 | 0 |

| T=10.99999 | Q=6.9 | ||||

| Average Inventory Units: | 0.63 | ||||

Time Lapse (T) = Total time between period beginning and period end.

Inventory Qty per Time (Q) = On Hand Inventory by total time between events.

Weighted Average Inventory Units = [Sum(Q)/T]

Ending Inventory Units

Table: SimulationOutputSiteProductDetail

Internal Name: EndingInventoryUnits

Displays the inventory remaining at the site at the end of the simulation run.

Minimum Inventory Units

Table: SimulationOutputSiteProductDetail

Internal Name: MinimumInventoryUnits

Displays the lowest value that the inventory for this product at this site ever reached throughout the simulation run.

Maximum Inventory Units

Table: SimulationOutputSiteProductDetail

Internal Name: MaximumInventoryUnits

Displays the highest value that the inventory for this product at this site ever reached throughout the simulation run.

Average Back Order Units

Table: SimulationOutputSiteProductDetail

Internal Name: AverageBackOrderUnits

Displays the time-weighted average back ordered quantity due to downstream sites for this product at this site in the specified period:

where:

B = Backorder Quantity

T = Time

P = Total time in the period

n = change in B

Maximum Back Order Units

Table: SimulationOutputSiteProductDetail

Internal Name: MaximumBackOrderUnits

Displays the highest quantity of back ordered units due to downstream sites at any point of time for this product at this site in the specified period.

Average In Transit Units

Table: SimulationOutputSiteProductDetail

Internal Name: AverageInTransitUnits

Displays the time-weighted average of units in-transit from all sources for this site:

where:

C = Units in transit to the site

T = Time

P = Total time in the period

n = change in C

Maximum In Transit Units

Table: SimulationOutputSiteProductDetail

Internal Name: MaximumInTransitUnits

Displays the highest value that the in-transit inventory for this product at this site ever reached throughout the simulation run.

Inventory Velocity

Table: SimulationOutputSiteProductDetail

Internal Name: InventoryVelocity

Displays the time that inventory is held before delivery to the customer.

Average Replenishment Quantity

Table: SimulationOutputSiteProductDetail

Internal Name: AverageReplenishmentQuantity

Displays the time-weighted average of units received at this site from all sources:

where:

R = Units received

T = Time

P = Total time in the period

n = change in R

Period

Table: SimulationOutputSiteProductDetail

Internal Name: Period

Displays the period number for the summary values. ALL indicates the record for the complete model horizon.

Average Order Cycle Time

Table: SimulationOutputSiteProductDetail

Internal Name: AverageOrderCycleTime

Displays the average of order cycle times (in DAYS) by site and product in the specified period from all sources. Order cycle time is the difference between the time the entire order was filled and the Due Date. If the value is negative, this is a measure of how much more quickly the cycles are being fulfilled compared to when they are due. If the Due Date is not set, it is treated as the end of time (also known as year 100000). In this case the order cycle time will be 0.

Due dates for sites can only be set in the Shipments or Productions tables. Internal replenishment orders (those generated by inventory policies) have no due date and thus order cycle time will be 0.

where:

A = Final delivery date

D = Due Date

n = orders completely received

Maximum Order Cycle Time

Table: SimulationOutputSiteProductDetail

Internal Name: MaximumOrderCycleTime

Displays the highest cycle time from all sources by site and product in the specified period. See Average Order Cycle Time for more details.

On Time Rate

Table: SimulationOutputSiteProductDetail

Internal Name: OnTimeRate

Displays the ratio of orders successfully produced or received on time at this site versus all orders produced or received. If there is no due date, the order is counted as on time. See Average Order Cycle Time for more details on Due Date.

D/R

where:

D = Orders produced or received at this site before the Due Date.

R = Orders produced or received at this site.

On Time Qty Rate

Table: SimulationOutputSiteProductDetail

Internal Name: OnTimeQtyRate

Displays the ratio of units produced or received on time at this site versus all units produced or received. If there is no due date, the order is counted as on time. See Average Order Cycle Time for more details on Due Date.

Q/R

where:

Q = Quantity produced or received at this site before the Due Date.

R = Quantity produced or received at this site.

Cycle Service Level

Table: SimulationOutputSiteProductDetail

Internal Name: CycleServiceLevel

Displays the ratio of shipments received or productions finished (when inventory is greater than zero) versus all shipments received or productions finished. A high number suggests that receipts or productions finish before inventory goes to zero. A low number suggests that there are more times when inventory is zero, risking out-of-stock to downstream sites.

Z/R

where:

Z = Orders produced or received at this site when inventory > zero.

R = Orders produced or received at this site.

Fill Rate

Table: SimulationOutputSiteProductDetail

Internal Name: FillRate

Displays the ratio of downstream orders immediately and completely filled when initially processed at this site versus all downstream orders. A higher rate indicates sufficient inventory available on hand when orders arrive to completely fulfill orders. Details can be found in the Order Report.

where:

F = Downstream orders filled completely when initially processed

D = Count of downstream orders

Fill Qty Rate

Table: SimulationOutputSiteProductDetail

Internal Name: FillQtyRate

Displays the percentage of units immediately filled when initially processed at this site. A higher rate indicates sufficient inventory on hand to fully or partially fulfill orders. Details can be found in the Order Report:

where:

P = Downstream-ordered units filled when initially processed

D = Quantity ordered from downstream

Ready Rate

Table: SimulationOutputSiteProductDetail

Internal Name: ReadyRate

The percentage of some inventory available in any given period; that is the fraction of time with positive stock available to fill orders:

where:

ZT = Zero-inventory time

P = Time in the period

Ending Orders

Table: SimulationOutputSiteProductDetail

Internal Name: EndingOrders

Displays the number of outstanding upstream orders at the end of the period which have yet to be filled. A shipment that has not arrived is included in Ending Orders. An order partially filled will result in a percentage unfilled. For example, an original order for 10 has had 7 units filled but 3 are still waiting - Ending Orders will be 0.30.

Ending Order Qty

Table: SimulationOutputSiteProductDetail

Internal Name: EndingOrderQty

Displays the total number of outstanding upstream units at the end of the period which have yet to be filled.

Total Order Qty

Table: SimulationOutputSiteProductDetail

Internal Name: TotalOrderQty

Displays the total number of product units ordered upstream by this site during the specified period. This includes production orders at the site.

Ending Back Orders

Table: SimulationOutputSiteProductDetail

Internal Name: EndingBackOrders

Displays the number of downstream orders that are on back order at this site at the end of the specified period; that is, the number of orders that are unfulfilled for downstream locations.

Ending Back Order Qty

Table: SimulationOutputSiteProductDetail

Internal Name: EndingBackOrderQty

Displays the sum of downstream product units that are on back order at this site at the end of the specified period; that is, the number of units that are unfulfilled for downstream locations.

Total Back Order Qty

Table: SimulationOutputSiteProductDetail

Internal Name: TotalBackOrderQty

Displays the total number of back ordered product units in the specified period. These are the order units that cannot be fulfilled using inventory when the order is initially processed.

For example, a distribution center receives 5 orders of 10 units each from a customer. Throughout the modeling time, this DC has only 10 units of inventory with no replenishment; the Total Back Order Units at the DC is 40 units.

Total Downstream Demand

Table: SimulationOutputSiteProductDetail

Internal Name: TotalDownstreamDemand

Displays the total quantity ordered for this product at this site in the specified period.

Lost Downstream Demand

Table: SimulationOutputSiteProductDetail

Internal Name: LostDownstreamDemand

Displays the number of demand units that were canceled or lost during the specified period. Lost demand occurs when Allow Back Orders in the Site Sourcing Policies table is set to “No”. If a site is chosen through sourcing but the site cannot fill the order, the balance of the order is counted as lost demand. If the Allow Partial Fill flag is set to “Yes” for this site/product in the Inventory Policies table, the site will fill as much of the order as possible before sending the rest to Lost Downstream Demand. If the Allow Partial Fill flag is set to “No” in this situation, all ordered units are lost. Demand units can also be canceled if the Cancel If Late field is set to “Yes” in the Demand or Shipments tables. Any remaining balance on an order when the time of order processing is greater than the Due Date will be added to Lost Downstream Demand. This is a customer-facing metric only.

Lost Downstream Demand Revenue

Table: SimulationOutputSiteProductDetail

Internal Name: LostDownstreamDemandRevenue

Displays the lost revenue due to demand units that were canceled or lost during the specified period. See Lost Downstream Demand for more details.

Total Shipped Qty

Table: SimulationOutputSiteProductDetail

Internal Name: TotalShippedQty

Displays the number of units of this product shipped from this site.

Total Shipped Value

Table: SimulationOutputSiteProductDetail

Internal Name: TotalShippedValue

Displays the value of this product shipped from this site in the specified period.

Total Shipped Weight

Table: SimulationOutputSiteProductDetail

Internal Name: TotalShippedWeight

Displays the value of this product shipped from this site in the specified period.

Total Shipped Cubic

Table: SimulationOutputSiteProductDetail

Internal Name: TotalShippedCubic

Displays the cubic volume of this product shipped from this site in the specified period.

Total Orders

Table: SimulationOutputSiteProductDetail

Internal Name: TotalOrders

Displays the total number of orders for this product shipped from this site in the specified period.

Expired Units

Table: SimulationOutputSiteProductDetail

Internal Name: ExpiredUnits

Displays the number of product units that have expired at the site due to shelf life considerations. When you populate the Shelf Life column in the Products table, those products still at the site when the shelf life is reached will be expired.

Scenario ID

Table: SimulationOutputSiteProductDetail

Internal Name: ScenarioID

Displays the identifier of the scenario for which the summary data was generated.

Sub-Scenario ID

Table: SimulationOutputSiteProductDetail

Internal Name: StepNumber

Displays the identifier of the sub-scenario, if applicable, for which the summary data was generated.

Rep

Table: SimulationOutputSiteProductDetail

Internal Name: Rep

Displays the replication number that the data on this row applies to.

Last modified: Wednesday May 15, 2024