Rolling Horizon Inventory Policy Summary

Internal Table Name: InvOptimOutput_TimePhasedInventorySummary

The Rolling Horizon Inventory Policy Summary table reports the results of Safety Stock Optimization by site-product-date when using Rolling Horizon Modeling. The Date is based on the Forecast Time Bucket on the Safety Stock Optimization: Advanced tab in Inventory Optimization Options.

Scenario

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: Not Applicable (Scenario column not in table)

The scenario for which the output data was generated.

Site Name

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: SiteName

The name of the site at which the product is held.

Product Name

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: ProductName

The name of the product held at the site.

Period Name

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: PeriodName

The period to which the safety stock and inventory policy applies.

Date

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: Date

The date for which the inventory policy summary information applies. This value is based on the Forecast Time Bucket on the Safety Stock Optimization: Advanced tab in Inventory Optimization Options. For example, if you have defined Weekly aggregation, records in this table will increment in weekly intervals.

Target Service Level

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: TargetServiceLevel

The Service Requirement value specified in the Inventory Policies table. Safety Stock Optimization will optimize the safety stock to satisfy the given target service level. This field will be left blank when Safety Stock is zero for the site-product. The default Target Service Level for the customer-facing site is set to 0.95.

Service Type

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: ServiceType

The Service Definition used for the output calculation for the product at the site during the period. This is usually the same as the Service Definition value in Optimization Options > Safety Stock Options.

| Type 1: Probability based |

The probability of no stock-out during the risk period. |

Event-oriented Concerned with whether a shortage occurs during the risk period. |

| Type 2: Quantity based |

The percentage of demand fulfilled from stock on time (Quantity Fill Rate). |

Quantity-based Interested in the percentage of demand satisfied on time. |

| Type 3: Time based |

The fraction of time with positive stock on hand. |

Time based Interested in both the shortage event and its duration. |

Batch-size Q = max (Minimum Order Quantity, Replenishment Frequency * Daily Demand Mean).

If batch size information is not provided, Safety Stock Optimization will use the Type 1 service type calculation automatically due to the lack of required information.

Safety Stock

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: SafetyStock

The optimized amount of safety stock that should be held to account for unknown variations in demand or lead time.

Excess Safety Stock

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: ExcessSafetyStock

This field displays the difference between the Minimum Safety Stock as defined in the Inventory Policies table and the calculated optimal safety stock. Safety Stock is the optimized amount of safety stock you must carry to satisfy the target service level. However, you may want to carry more than the optimized safety stock. In this case, you can input a Minimum Safety Stock that is greater than the optimal safety stock. When the Minimum Safety Stock > optimal safety stock, the difference is reported as Excess Safety Stock.

Total Safety Stock

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: TotalSafetyStock

This field displays the sum of the Safety Stock and Excess Safety Stock.

USF Safety Stock

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: USFSafetyStock

This is safety stock that covers an upstream service failure (USF). In cases where an upstream site has lower service than a downstream site, the downstream site carries safety stock reported in USF Safety Stock to account for the lower upstream service.

Safety Stock DOS

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: SafetyStockDOS

The equivalent number of days of supply (DOS) to be held in inventory as safety stock to account for unknown variations in demand or lead time. Safety Stock DOS is derived as:

Safety Stock/Daily Demand Mean

Daily Demand Mean is calculated as:

(aggregated) Demand Mean/Average number of days in aggregation level)

This value is in DAYS.

Safety Stock Cost

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: SafetyStockCost

The cost of holding the safety stock.

Safety Stock Cost = (Total Safety Stock * Product Value * Inventory holding cost % * Period Length/365 days) + (Total Safety Stock * Unit Storage Cost).

The Period Length is affected by the Work Week setting in Safety Stock Options. For example, if your Period is one year and the Work Week is 7 Days, the Period Length is 365. If the Work Week is 5 Days, the length is 261. You can see the period length in the Aggregation Level field in the Customer Demand Profile table.

If you have populated Start Date and End Date in the Products table, and the resulting product lifetime falls within the model horizon, the product lifetime is used as the Period Length when calculating Safety Stock Cost. If the product lifetime falls outside the horizon, the regular period length value is used.

Safety Stock Value

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: InventoryValue

The total product value of the safety stock.

Safety Stock Value = Safety Stock * Product Value

Coverage

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: Coverage

The optimized net period of risk (in days) that a site's safety stock will cover. Also known as the "net replenishment lead time". Coverage is equal to this site's immediate lead time, plus the service time quoted by its nearest source, minus the service time this site quotes to its customer or nearest downstream sites. When the site has multiple sources or destinations, coverage is calculated from the combination of coverage for each source-site-destination.

Daily Demand Mean

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: DemandQtyMean

Daily Demand Mean is calculated as:

(aggregated) Demand Mean / Average number of days in aggregation level

Daily Demand Std Dev

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: DemandQtyStdDev

Daily Demand Std Dev is calculated as:

(aggregated) Demand Standard Deviation / SQRT(Average number of days in aggregation level)

Demand Class Details

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: DemandClassDetails

Demand Class Details summarizes the demand class from four different aspects. This is the class that Safety Stock Optimization uses to determine Lead-Time Demand Distribution and which inventory policy is recommended.

Recommended Policy

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: RecommendedPolicy

The inventory control policy that is appropriate for demand at the site for the product in order to maintain the service requirement.

Policy Parameter 1

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: PolicyParameter1

The first parameter as determined based on the Recommended Policy. For example, if the Recommended Policy is (R,Q), Policy Parameter 1 will be the value for the Reorder Point (R). If the Recommended Policy is (s,S), Policy Parameter 1 will be the value for the Report Point (s).

For additional information, refer to Policy Parameters.

Policy Parameter 2

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: PolicyParameter2

The first parameter as determined based on the Recommended Policy. For example, if the Recommended Policy is (R,Q), Policy Parameter 2 will be the value for Reorder Qty (Q). if the Recommended Policy is (R,Q), Policy Parameter 2 will be the value for Reorder Up To Qty (S).

For additional information, refer to Policy Parameters.

Expected Type 1 Service

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: Type1Service

The expected Type 1 service level met by the recommended safety stock and inventory policy. When Service Definition = Type 1, the value will be the same as the Target Service Level for “Continuous” products, and greater than or equal to the Target Service Level for “Discrete” products. For example, 9.5 liters of water will satisfy exactly 0.95 service requirements. However, if water is packed 1 liter per bottle, then it must be rounded up to 10 bottles to satisfy 0.95 service requirements. Since 10 Liters > 9.5 Liters, the expected service level will be higher than 0.95.

Expected Type 2 Service

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: Type2Service

The expected Type 2 service level met by the recommended safety stock and inventory policy. When Minimum Order Quantity (Q) or Replenishment Frequency or both are not provided, this field is calculated based on Q = 1. You must provide Minimum Order Quantity (Production Policies) or Replenishment Frequency (Transportation Policies) if Type 2 is used as a target service level to calculate safety stock. When Service Definition = Type 2, the value will be the same as the Target Service Level for “Continuous” products, and greater than or equal to the Target Service Level for “Discrete” products. For example, 9.5 liters of water will satisfy exactly 0.95 service requirements. However, if water is packed 1 liter per bottle, then it must be rounded up to 10 bottles to satisfy 0.95 service requirements. Since 10 Liters > 9.5 Liters, the expected service level will be higher than 0.95.

Expected Type 3 Service

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: Type3Service*

The expected Type 3 service level met by the recommended safety stock and inventory policy. When Minimum Order Quantity (Q) or Replenishment Frequency or both are not provided, this field is calculated based on Q = 1. You must provide Minimum Order Quantity (Production Policies) or Replenishment Frequency (Transportation Policies) if Type 2 is used as a target service level to calculate safety stock. When Service Definition = Type 2, the value will be the same as the Target Service Level for “Continuous” products, and greater than or equal to the Target Service Level for “Discrete” products. For example, 9.5 liters of water will satisfy exactly 0.95 service requirements. However, if water is packed 1 liter per bottle, then it must be rounded up to 10 bottles to satisfy 0.95 service requirements. Since 10 Liters > 9.5 Liters, the expected service level will be higher than 0.95.

Lead Time Demand Dist

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: LeadTimeDist

The distribution used to represent the demand during risk period (coverage). This is determined by Demand Class Details and lead time demand parameters.

Lead Time Demand Mean

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: LeadTimeMean

The average demand during lead-time. This is derived by:

Demand Mean * Coverage

For more information, refer to Lead Time in Safety Stock Optimization.

Lead Time Demand Std Dev

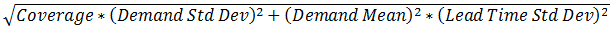

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: LeadTimeStdDev

The standard deviation of demand during risk period (coverage). This is defined by:

For more information, refer to Lead Time in Safety Stock Optimization.

Avg Backorders

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: AvgBackorders

The long-run time weighted average of backorders (shortage).

Avg Inventory

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: AvgInventory

The long-run time-weighted average on-hand inventory levels.

Avg Replenishment Qty

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: AvgReplenishmentQty*

The average size of replenishment orders. This is greater than or equal to Min Replenishment Qty.

For example, assume the order quantity Q = 4. Depending on the demand, the replenishment orders will vary. Assume that on day 1, the total replenishment order is 1 * Q = 4 (ordering in multiples of Q). On day 2, the replenishment order is 4 * Q = 16. On day 3, the replenishment order is 3 * Q = 12. In this case, the Avg Replenishment Qty is (4+16+12)/3 = 11.

Sourcing Type

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: SourcingType

Identifies if the site is sourcing the product from a single site or multiple source(s)/mode(s) during the period. If the site has multiple sources for the product, the recommended inventory policy for each source is found the in Inventory Policy Details table.

Cycle Stock

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: CycleStock

Cycle Stock is the stock on hand to satisfy regular sales orders or demand from downstream sites, excluding the safety stock. It is calculated as:

Cycle Stock = Batch size / 2 = max [MOQ (Min Order Qty), EOQ (Economic Order Qty), Replenishment Frequency * Daily Demand Mean] / 2

EOQ is computed as:

where:

D = Annual demand (units)

S = Fixed Order Cost ($)

C = Cost per unit ($)

I = Holding cost (%)

H = Holding cost ($) = I x C

Cycle Stock Cost

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: CycleStockCost

Cycle Stock Cost is the cost incurred to hold Cycle Stock. It is calculated as:

Cycle Stock Cost = Cycle Stock * Product Value * Inventory holding cost % * Period Length / 365 days.

Work In Progress Inventory

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: WorkInProgressInventory*

Work In Progress is the materials and components that have begun their transformation to finished goods. It is calculated as:

Work In Progress = Product Time * Demand Mean / 2

Work In Progress Inventory Cost

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: WorkInProgressInventoryCost

Work In Progress Cost is the cost incurred to hold Work In Progress Inventory. It is calculated as:

Work In Progress Cost = Work in Progress * Product Value * Inventory Holding Cost % * Period Length / 365 days

Incoming In Transit Inventory

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: IncomingInTransitInventory

Incoming In Transit Inventory is goods that have shipped from the source location but have not yet arrived at the destination location. It is calculated as:

Incoming In Transit Inventory = Transportation Time * Demand Mean

Incoming In Transit Inventory Cost

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: IncomingInTransitInventoryCost

Incoming In Transit Inventory Cost is the cost incurred to hold Incoming In Transit Inventory. It is calculated as:

Incoming In Transit Inventory Cost = Incoming In Transit Inventory * Product Value * Inventory Holding Cost % * Period Length / 365 days

Total Inventory

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: TotalInventory

The Total Inventory is calculated as:

Total Inventory = Total Safety Stock + Cycle Stock + Incoming In Transit Inventory + Work In Progress

Total Inventory Cost

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: TotalInventoryCost

The Total Inventory Cost is the cost to hold all inventory. It is calculated as:

Total Inventory Cost = Total Inventory * Product Value * Inventory Holding Cost % * Period Length/365 days

Total Inventory Value

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: TotalInventoryValue

The Total Inventory Value is the value of all inventory currently held. It is calculated as:

Total Inventory Value = Total Inventory * Product Value

Status

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: Status

Reports if this Site-Product-Period combination was successful or was skipped.

Sub-Model ID

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: SubModelID

Provides the internal sub-model identifier used during optimization.

Scenario ID

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: ScenarioID

The identifier of the scenario for which the summary data was generated.

Sub-Scenario ID

Table: InvOptimOutput_TimePhasedInventorySummary

Internal Name: StepNumber

The identifier of the sub-scenario, if applicable, for which the summary data was generated.

Last modified: Wednesday May 15, 2024