Modeling process linking

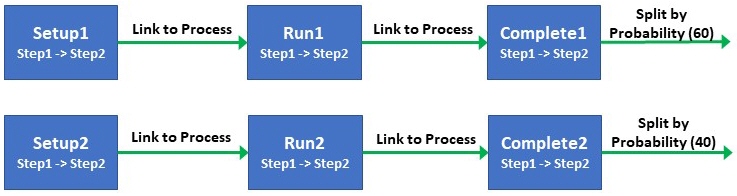

When you create processes, such as production processes, you can link one process to another. To illustrate, we will set up 3 Production Processes and their associated Production Process Steps, then use the Production Process Assignments table to link one process to the next. In this case, the three processes are run (Setup -> Run -> Complete), with probability determined by the final process:

The Production Processes are defined as follows:

|

Name |

Type |

|

Setup1 |

Start Production |

|

Setup2 |

Start Production |

|

Run1 |

Run Production |

|

Run2 |

Run Production |

|

Complete1 |

Complete Production |

|

Complete2 |

Complete Production |

The Production Process Steps are defined as follows:

|

Period |

Process |

Process Step |

Next Process Step |

|

(ALL_Periods) |

Setup1 |

Step1 |

Step2 |

|

(ALL_Periods) |

Setup1 |

Step2 |

(None) |

|

(ALL_Periods) |

Setup2 |

Step1 |

Step2 |

|

(ALL_Periods) |

Setup2 |

Step2 |

(None) |

|

(ALL_Periods) |

Run1 |

Step1 |

Step2 |

|

(ALL_Periods) |

Run1 |

Step2 |

(None) |

|

(ALL_Periods) |

Run2 |

Step1 |

Step2 |

|

(ALL_Periods) |

Run2 |

Step2 |

(None) |

|

(ALL_Periods) |

Complete1 |

Step1 |

Step2 |

|

(ALL_Periods) |

Complete1 |

Step2 |

(None) |

|

(ALL_Periods) |

Complete2 |

Step1 |

Step2 |

|

(ALL_Periods) |

Complete2 |

Step12 |

(None) |

The Production Process Assignments are defined as follows, with an Assignment Policy of “Link to Process” for the first two processes. The Policy Parameter is the name of the process to which it is linked. For the final process (“Complete”), we are using “Split by Probability” as the Assignment Policy. We can then use the Policy Parameter to determine the allocation to each process line:

|

Period |

Site |

Product |

Process |

Assignment Policy |

Policy Parameter |

|---|---|---|---|---|---|

|

(ALL_Periods) |

(ALL_Sites) |

(ALL_Products) |

Setup1 |

Link to Process |

Run1 |

|

(ALL_Periods) |

(ALL_Sites) |

(ALL_Products) |

Setup2 |

Link to Process |

Run2 |

|

(ALL_Periods) |

(ALL_Sites) |

(ALL_Products) |

Run1 |

Link to Process |

Complete1 |

|

(ALL_Periods) |

(ALL_Sites) |

(ALL_Products) |

Run2 |

Link to Process |

Complete2 |

|

(ALL_Periods) |

(ALL_Sites) |

(ALL_Products) |

Complete1 |

Single Process |

|

|

(ALL_Periods) |

(ALL_Sites) |

(ALL_Products) |

Complete2 |

Single Process |

|

With demand for 100 units, when the solve is complete, the Production Process Flows are as shown below:

|

Period Name |

Site Name |

Product Name |

Process Type |

Process Name |

Process Step Name |

Next Process Step Name |

Flow Units |

|---|---|---|---|---|---|---|---|

|

SINGLEPERIOD |

MFG |

Product |

Start Production |

Setup1 |

Step1 |

Step2 |

60.00 |

|

SINGLEPERIOD |

MFG |

Product |

Start Production |

Setup1 |

Step2 |

|

60.00 |

|

SINGLEPERIOD |

MFG |

Product |

Start Production |

Setup2 |

Step1 |

Step2 |

40.00 |

|

SINGLEPERIOD |

MFG |

Product |

Start Production |

Setup2 |

Step2 |

|

40.00 |

|

SINGLEPERIOD |

MFG |

Product |

Run Production |

Run1 |

Step1 |

Step2 |

60.00 |

|

SINGLEPERIOD |

MFG |

Product |

Run Production |

Run1 |

Step2 |

|

60.00 |

|

SINGLEPERIOD |

MFG |

Product |

Run Production |

Run2 |

Step1 |

Step2 |

40.00 |

|

SINGLEPERIOD |

MFG |

Product |

Run Production |

Run2 |

Step2 |

|

40.00 |

|

SINGLEPERIOD |

MFG |

Product |

Complete Production |

Complete1 |

Step1 |

Step2 |

60.00 |

|

SINGLEPERIOD |

MFG |

Product |

Complete Production |

Complete1 |

Step2 |

|

60.00 |

|

SINGLEPERIOD |

MFG |

Product |

Complete Production |

Complete2 |

Step1 |

Step2 |

40.00 |

|

SINGLEPERIOD |

MFG |

Product |

Complete Production |

Complete2 |

Step12 |

|

40.00 |

There are limitations in terms of how you define linked processes:

- The processes must be linked in the order in which they occur. In the example above, Setup is linked to Run and Run is linked to Complete.

- Assignment Policy values other than “Link to Process” must be placed on the final process. In the example above, we use “Split by Probability” on the Complete process. The earlier processes use “Link to Process”. This ensures that all processes in the series are used.

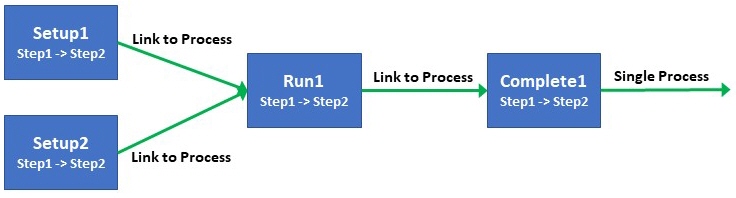

- You can link multiple processes to a single process (“many to one”).

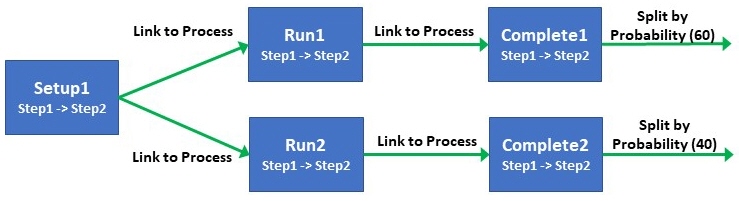

However, you cannot link a process to multiple processes (“one to many”). The following structure is infeasible:

- When you use “Link to Process”, the Production Process Assignments must have the same Period-Site-Product combination for the linked records. For Sourcing Process Assignments, the Period-Location-Product-Source combination must be the same between linked processes; the other process types have similar requirements.

- Links can be made only between processes of the same activity type; that is, production processes can only be linked to other production processes, not to sourcing processes.

- For processes that support 3 different Types, you do not need to define all 3. Be sure to link defined processes if required. You can “skip” the middle process (such as “Run Production”) as long as this process is not defined and you link the “Start Production” process to the “Complete Production” process.

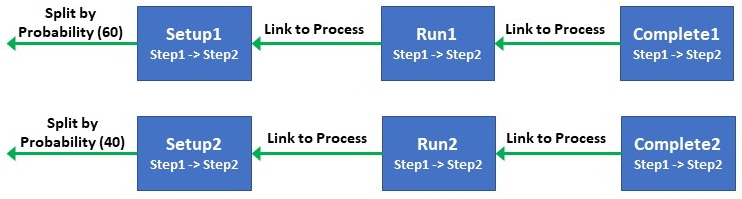

- While you can define the links in the reverse order (Complete -> Run -> Start), when the model is run, it is feasible, but ignores the links. In the example below, the probabilities are not enforced in the Run and Complete processes.

Last modified: Wednesday May 15, 2024