Hub optimization

Hub Optimization allows you to solve hub selection and zone skipping problems. It supports linehaul (long distance) routes from source locations to hubs and inter-hub movements.

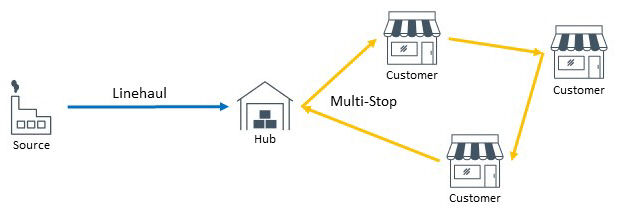

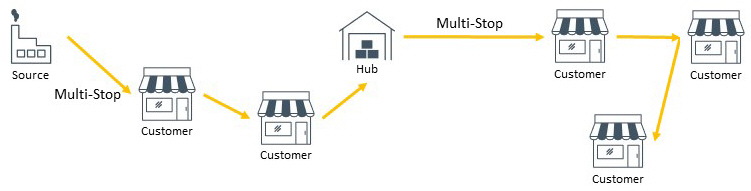

When using linehaul assets, the hub optimization problem determines if a linehaul is appropriate for travel to the hub. It then routes from the hub to customers with either multi-drop or direct routes. Hub optimization supports both consolidation hubs (multi-stop to the hub) and deconsolidation hubs (multi-stop from the hub).

Specifically, hub optimization provides the following abilities:

- Identifies if a shipment should go through a hub or not and, if so, which hub(s) it should use.

- Determines whether a shipment should go through a hub to take advantage of zone skipping cost and time efficiencies.

- Provides basic hub baseline definition, where you can force shipments through hubs.

- Supports fleet optimization and asset selection.

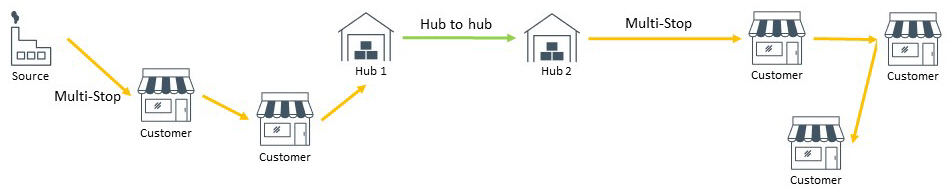

For example, hub optimization is designed to address networks such as the one shown below:

As with other problem types, Transportation Optimization will seek to minimize the routing cost. Transportation Optimization assesses:

- The cost of routing the shipment through a hub.

- The Direct Shipping Cost on the Shipments table (if provided).

- The cost of routing with regular multi-stop routes between shipment origin and destination.

If the cost of routing the shipment through a hub is the lowest cost and it does not violate the shipment time windows, the hub routing is used. The actual time to route when using a hub can be based on direct times inbound to and outbound from the hub as populated in the Hubs table. Any minimum time defined for cross-docking activities at the hub (dwell time) is also included in the time for hub routing. If routing through the hub violates shipment windows, the hub will not be selected for the shipment route.

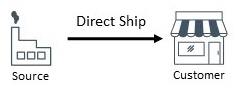

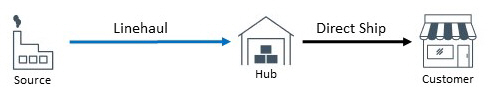

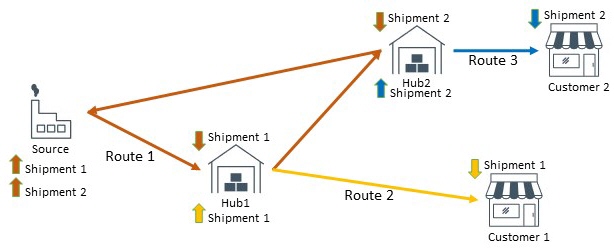

Based on the constraints and costs within your model, Transportation Optimization considers a number of routing options, such as those shown below:

In the last example, which shows a hub to hub movement, each shipment can only be dropped and picked up at a single hub. For example, Shipment 1 and Shipment 2 can be picked up at the Source on Route 1. Shipment 1 can be dropped at Hub 1, then picked up from this hub on Route 2 to be taken to the customer. Shipment 2 can be dropped at Hub 2, then picked up on Route 3 to be taken to the customer. See Hub optimization limitations for additional information.

Modeling linehaul transits

In hub optimization models, you can set up dedicated transportation assets that are to be used for the linehaul transit from the shipment sources to the hubs. If dedicated transportation assets are defined, linehaul transits use the dedicated assets instead of the assets for multi-stop routing. You define rates that apply to each of these asset types and assets used on linehaul lanes often have a fixed cost defined. The Asset Availability table defines not only how many assets are available at specific sites, but which shipment origin - hub combination pairs can be serviced by the asset. Use the Linehaul Source and Linehaul Destination columns to define the valid lanes.

Creating a basic hub optimization baseline

By default, shipments are routed through hubs when the solver determines it provides the best solution. You can force individual shipments to go through specific hubs by setting Force Through Hub to "Yes" in the Hubs table, providing a basic baseline function. Hub optimization does not currently support the use of Shipment Constraints to provide more detailed baseline information.

Hub optimization limitations

At this time, hub optimization does not support:

- Split shipments

- Multiple compartments

- Hub open/close decisions

- Baseline routing using Shipment Constraints

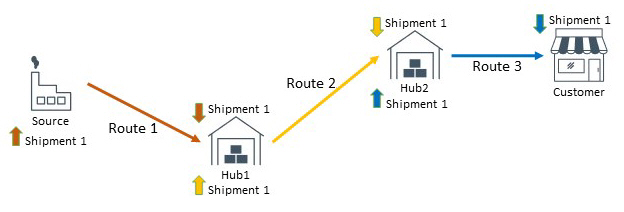

- Multi-echelon hub modeling for a shipment. For example, the following case is supported as each shipment is dropped and picked at only one hub:

while this case is not supported as Shipment 1 is dropped and picked at two different hubs:

Hub optimization inputs

- The inputs for Hub Optimization are generally the same as for Standard Optimization:

- Sites – You must have at least one pool site.

- Products - You must have at least one product defined.

- Transportation Assets – You must have at least one transportation asset defined. Define constraints such as capacity and operating parameters on the transportation asset. You will typically define assets that are specifically used for the linehaul from the shipment source to the hub. You define associated rates for these assets, and use columns on the Asset Availability table to define which sources and hubs these assets serve. You can specify the Rate Type (Location Independent, Origin Dependent, etc.) on the Transportation Assets table.

- Shipments – You must define one or more shipments.

- Rate – You must define one or more Rate records. For the rates associated with the assets that serve shipments from source locations to the hubs, you will typically define a Fixed Cost for this transport.

- Asset Availability – You must define one or more Asset Availability records, to determine how many transportation assets are available at specific sites. Columns on the Asset Availability table that are significant for hub optimization include:

- Site – This location is where the asset is housed. It may be the source location of shipments or a domicile from which vehicles can be positioned to one or more shipment source locations.

- Asset – For assets that are used between the shipment source and the hub, this is often a vehicle used for full truckload linehauls.

- Linehaul Source – Use this column to identify the source location or group of source locations that the asset can use. The asset will be limited to linehaul routes between the Linehaul Source and the Linehaul Destination locations.

- Linehaul Destination – Use this column to identify the destination location or group of destination locations that the asset can use. The destination locations are the hubs that the asset can serve. The asset will be limited to linehaul routes between the Linehaul Source and the Linehaul Destination locations.

- Hubs – Use this table to identify which sites are available for selection as hubs by shipment or shipment group.

- Hub – Select the site name of the hub. Eligible values are sites that have Type = “Existing Site”.

- Shipment – Select the shipment name or shipment group name of the shipments associated with the hub.

- Min Dwell Time – Enter the minimum time that the shipment is to remain at the hub. The dwell time is typically used to represent cross-docking and other transfer activities at the hub. The default time unit is DAY as defined in Model Settings.

- Max Dwell Time – Enter the maximum time that the shipment can remain at the hub. The dwell time is typically used to represent cross-docking and other transfer activities at the hub. The default time unit is DAY as defined in Model Settings.

- Direct Cost Out – Enter the cost of the outbound movement of the shipment from the hub direct to its end destination. In other words, this is the cost for a non-multi stop route out of the hub to its final destination. It acts as an override to the calculated cost.

- Direct Cost In – Enter the cost of the inbound movement of the shipment direct to the hub. In other words, this is the cost for a non-multi stop route into the hub from the shipment origin. It acts as an override to the calculated cost.

- Direct Inbound Hub Time – Enter the time required for the inbound movement of the shipment direct to the hub. This is the time required for a non-multi stop route into the hub from the shipment origin. It acts as an override to the calculated route time. If you do not provide a value for this time, Transportation Optimization will calculate the time during route creation. The default time unit is DAY as defined in Model Settings.

- Direct Outbound Hub Time – Enter the time requirement for the outbound movement of the shipment from the hub direct to its end destination. This is the time required for a non-multi stop route out of the hub to its final destination. It acts as an override to the calculated route time. If you do not provide a value for this time, Transportation Optimization will calculate the time during route creation. The default time unit is DAY as defined in Model Settings.

- Force Through Hub – When this value is "Yes", the shipment will be forced through the hub. This enables you to do basic baseline modeling of your hubs.

You can optionally define Business Hours, Transit Matrix records, and Relationship Constraints as you need them for your modeling.

Hub optimization high level algorithm summary

The following provides a high level review of the hub optimization algorithm:

- Initial Solution Construction phase:

- Create multiple paths for each shipment;

- Use heuristics and route generation to create and augment routes by each asset and asset location.

- Solution building phase:

- A mixed integer program is used to select routes, paths, hubs, modes (or asset reuses for fleet opt).

- Solution improvement phase:

- Try to insert unrouted shipments into the feasible solution, check if solution is improved.

- Post process and report.

Last modified: Wednesday May 15, 2024