Flexible single echelon modeling

Safety Stock Optimization offers a flexible single echelon modeling method that takes constraints into account and is able to quickly calculate safety stock and service time. This method is a significant improvement over standard single echelon modeling. With standard single echelon modeling:

-

Each site/product combination is independent.

-

As a result of the independent structure, each site must hold safety stock to handle its own uncertainty.

-

Constraints, such as Maximum Safety Stock, can cause infeasibility or they get ignored.

Flexible single echelon modeling offers a fast calculation based on pulling stock downstream as needed:

-

Sites are dependent.

-

Starting at the most upstream site, each site holds the maximum coverage that constraints allow. At the site immediately downstream, the incoming service time is dynamically calculated based on the upstream constraints.

-

Stock is not pushed downstream unless there is an outbound service time constraint.

-

The flexible single echelon calculation is faster than a traditional single echelon optimization.

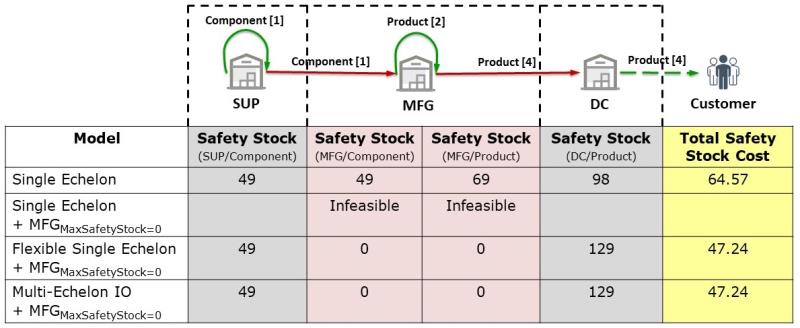

As an illustration, consider the following network:

When the Maximum Safety Stock = 0 constraint is applied to the MFG site, flexible single echelon modeling automatically pushes the safety stock from the MFG site to the downstream site to obtain a feasible solution.

Last modified: Wednesday May 15, 2024