Network Optimization constraints

These constraints enable you to limit flow over lanes, production at sites, and inventory held at sites. In addition to these constraints, you can also use Count constraints to limit the number of sites, work centers, flows, inventory and production locations to be used within a model structure.

Flow constraints

Flow constraints place restrictions on the amount of goods traveling between sites.

The dimensions of a flow constraint are:

- Source Site: The source of the flow

- Destination Site: The destination of the flow

- Product: The product flowing

- Mode: The method of transportation

- Period: The time in which the flow occurs

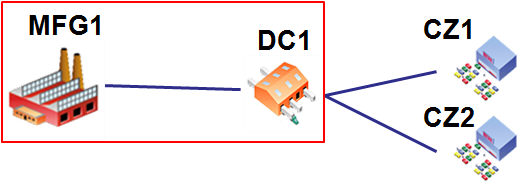

For example, let’s take a look at flow constraint that can be placed between a MFG and DC.

"No more than 500 units of product A can be transported from MFG1 to DC1"

3 of the 5 dimensions of a flow are in use for this constraint: source site, destination site, and product. Since the constraint did not specify a mode or time period, assume (as the software will) that the constraint between MFG1 and DC1 is for ALL modes and ALL periods. In other words, the constraint applies across all the modes and all the periods under consideration.

To understand how to apply the "no more than 500 units" component of the constraint, please view the sections on Constraint types.

Keep in mind that when using Shipments with Network Optimization, Flow Constraints with a Constraint Type of "Min" are generated based on the Source values. The Destination for the flow constraint will be set to "(ALL)". See Shipments for additional information.

Inventory constraints

Inventory constraints place restrictions on the amount goods being held at sites.

The dimensions of an inventory constraint:

- Site: The place where inventory is held

- >Product: The product being held

- Period: The time in which inventory is held

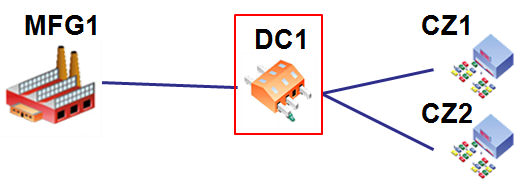

For example, let’s take a look at inventory constraint that can be placed at facilities (e.g. DC).

"No more than 500 units of product A can be held at DC1"

2 of the 3 dimensions of an inventory are in use for this constraint: site and product. Since the constraint did not specify a time period, assume (as the software will) that the constraint at DC1 is for ALL periods.

To understand how to apply the "no more than 500 units" component of the constraint, please view the sections on constraint type and constraint basis.

Production constraints

Production constraints place restrictions on the amount of goods produced at sites.

The dimensions of a production constraint are:

- Site: The locations where production takes place

- Product: The product being produced

- Period: The time in which the production occurs

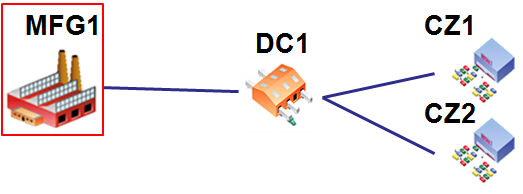

For example, let’s take a look at production constraint that can be placed on MFG1.

"No more than 200 units of product A can be produced at MFG1"

2 of the 3 dimensions of a production are in use for this constraint: site and product. Since the constraint did not specify a time period, assume (as the software will) that the constraint at MFG1 is over ALL periods.

To understand how to apply the "no more than 200 units" component of the constraint, please view the sections on constraint type and constraint basis.

Last modified: Wednesday May 15, 2024